Categoria

Serbatoi di propano GPL da 50000 litri e stoccaggio di accessori

Panoramica Descrizione del prodotto Serbatoio di stoccaggio del GPL HONGTU ha la capacità di progettazione e fabbricazio

Overview

Informazioni basilari.

| Modello numero. | 5sdxfsd |

| Condizione | Nuovo |

| Indennità di corrosione | 1,0 mm o personalizzato |

| Pressione di prova idraulica | 2,22 MPa/2,25 MPa o personalizzato |

| Temperatura di progetto | -20/50 Gradi o Personalizzati |

| Spessore del disegno della testa | Personalizzato |

| Norma di progettazione | ASME/GB |

| Spessore del design del guscio | Personalizzato |

| Pressione di progetto | 1,61 MPa/1,724 MPa o personalizzato |

| Temperatura di lavoro | -20~50 gradi o personalizzato |

| Mawp | 1,77 MPa/1,724 MPa o personalizzato |

| Carico utile | 0,25~500 tonnellate o personalizzate |

| Pressione lavorativa | Meno di 1,61 MPa/1,724 MPa o personalizzato |

| Capacità | 0,5~1000 M3 o personalizzato |

| Pacchetto di trasporto | Normale |

| Specifica | Personalizzato |

| Marchio | CIMC HONTO |

| Origine | Cina |

| Codice SA | 73110090 |

| Capacità produttiva | 2000/Anno |

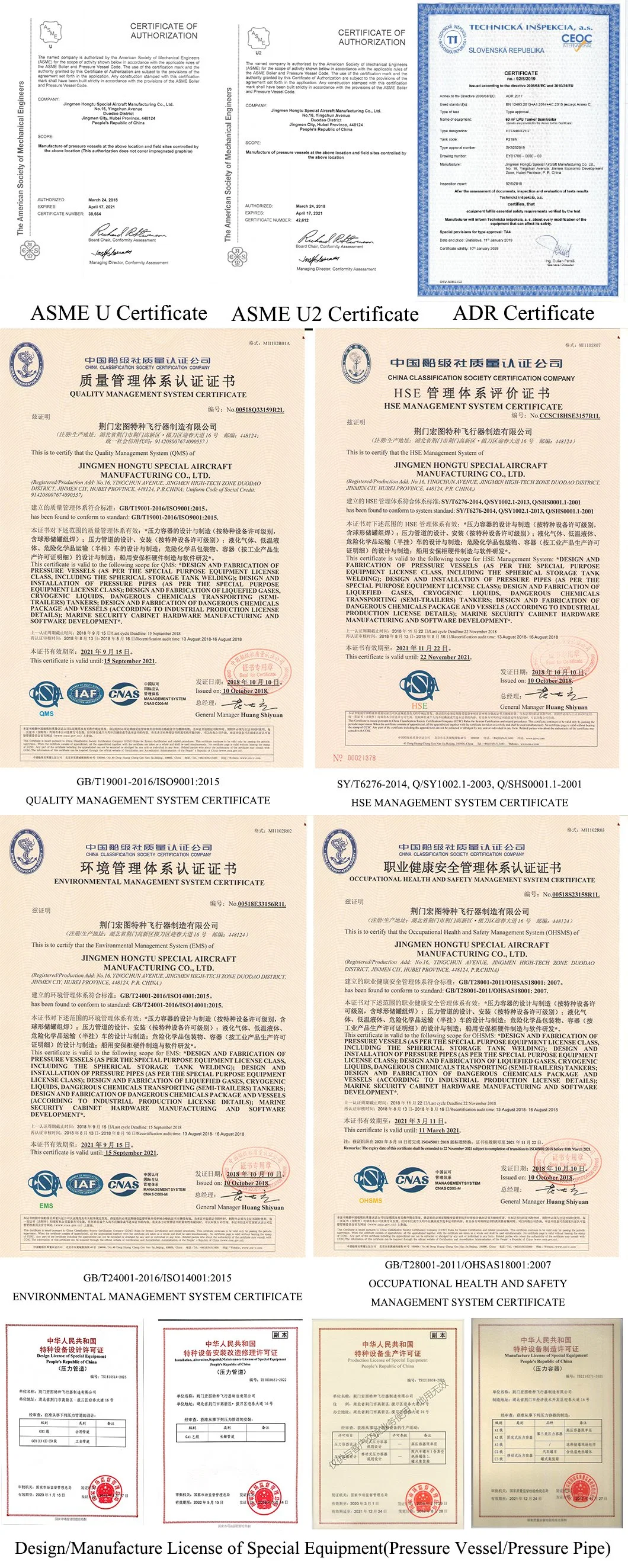

01 Powerful R&D AbilityHONGTU has been rated as "Hubei Province Technical Center for Pressure Vessels", "Hubei Province Workstation for High-skilled Talents", etc. We have acquired more than 120 patents through the "Producing, Learning and Researching" practice, and frequent technical communications and cooperation with China Standardization Committee on Boilers and Pressure Vessels, China Classification Society, Tsinghua University, Shanghai Jiao Tong University, Zhejiang University, FuzhouUniversity, Huazhong University of Science and Technology, YPDI(Nanjing Yangzi Petrochemical Design Engineering Co., Ltd.), Burg Industries B.V., TGE GAS INVESTMENT SA, Department of Energy Business(DOEB in Thailand), Australia MLI company, and other Government agencies at home and abroad, Universities, famous companies in the industry.02 Top Expert TeamWe have more than 330 professional technical staff, 30 senior engineers(including 5 Researcher-level Engineers), about 500 staff who are multi-skilled technical talents and senior technicians, 9 outsourced experts and professors employed in the industry. We are the Editorial Board of the China National Boards of Supervision Regulation on Safety Technology for Transportable Pressure Vessel; We have participated in the compiling of many other standards, such as Road Tanker for Liquefied Gas, Road Tankers for Cryogenic Liquid, Supervision Regulation on Safety Technology for Transportable Pressure Vessel, Road Tanker for Dangerous Liquid Goods Transportation.03 Strong Production CapacityHONGTU has been facilitated with more than 2000 sets of equipment, such as plasma cutting machines, US Lincoln welding machines, welding robots, all kinds of large and medium-sized rolling machines, beveling machines, cranes, heat treatment furnace, NDT equipment, 2000 tons of spherical shell press machines and other large heavy equipment. Among them, there are more than 200 sets of testing equipment.04 Comprehensive Industrial Chain SolutionHONGTU has been engaged in manufacturing of energy and chemical storage & transportation equipment for over 3 decades. Focusing on the production, storage and transportation, application and intensive processing of upstream, midstream and downstream liquefied petroleum gas industry chain, HONGTU forms complete industrial equipment cluster from oil refining device, spherical tank, large scale flat bottomed vertical tank to mounded type tank, from lightweight and large-volume liquefied gas tanker to core equipment manufacturing of various types of end applications and engineering application, is China's only LPG whole industry chain equipment manufacturer and solution provider.05 Scientific and Reorous QA&QC SystemHONGTU has a sound quality assurance system and perfect quality control procedures. Products from the entry of raw materials to the delivery to the user must pass 111 quality control points, 243 quality control procedures and 47 procedure document reviews. Annual radiographic inspection films of the products exceed more than 400,000 copies and each product quality files keep for more than 20 years, so each weld quality can be tracked. HONGTU continues to carry out the LEAN Management, introduce the ONE module, passes the HSE system(quality, occupational health and safety, environment) certification and realizes the comprehensive management of information, quality and workers in the manufacturing site.06 Professional International Services and Marketing NetworkHONGTU has its own international business network and a sound international business organization structure, including 50 plus professionals engaged in technical service and overseas marketing, dedicated to providing overseas customers with technical consultation, business negotiation, product service, personnel training and a full range of integrated solutions services, and has built a three-level service assurance system comprised of salesperson, engineer and professional service personnel.

01 Powerful R&D AbilityHONGTU has been rated as "Hubei Province Technical Center for Pressure Vessels", "Hubei Province Workstation for High-skilled Talents", etc. We have acquired more than 120 patents through the "Producing, Learning and Researching" practice, and frequent technical communications and cooperation with China Standardization Committee on Boilers and Pressure Vessels, China Classification Society, Tsinghua University, Shanghai Jiao Tong University, Zhejiang University, FuzhouUniversity, Huazhong University of Science and Technology, YPDI(Nanjing Yangzi Petrochemical Design Engineering Co., Ltd.), Burg Industries B.V., TGE GAS INVESTMENT SA, Department of Energy Business(DOEB in Thailand), Australia MLI company, and other Government agencies at home and abroad, Universities, famous companies in the industry.02 Top Expert TeamWe have more than 330 professional technical staff, 30 senior engineers(including 5 Researcher-level Engineers), about 500 staff who are multi-skilled technical talents and senior technicians, 9 outsourced experts and professors employed in the industry. We are the Editorial Board of the China National Boards of Supervision Regulation on Safety Technology for Transportable Pressure Vessel; We have participated in the compiling of many other standards, such as Road Tanker for Liquefied Gas, Road Tankers for Cryogenic Liquid, Supervision Regulation on Safety Technology for Transportable Pressure Vessel, Road Tanker for Dangerous Liquid Goods Transportation.03 Strong Production CapacityHONGTU has been facilitated with more than 2000 sets of equipment, such as plasma cutting machines, US Lincoln welding machines, welding robots, all kinds of large and medium-sized rolling machines, beveling machines, cranes, heat treatment furnace, NDT equipment, 2000 tons of spherical shell press machines and other large heavy equipment. Among them, there are more than 200 sets of testing equipment.04 Comprehensive Industrial Chain SolutionHONGTU has been engaged in manufacturing of energy and chemical storage & transportation equipment for over 3 decades. Focusing on the production, storage and transportation, application and intensive processing of upstream, midstream and downstream liquefied petroleum gas industry chain, HONGTU forms complete industrial equipment cluster from oil refining device, spherical tank, large scale flat bottomed vertical tank to mounded type tank, from lightweight and large-volume liquefied gas tanker to core equipment manufacturing of various types of end applications and engineering application, is China's only LPG whole industry chain equipment manufacturer and solution provider.05 Scientific and Reorous QA&QC SystemHONGTU has a sound quality assurance system and perfect quality control procedures. Products from the entry of raw materials to the delivery to the user must pass 111 quality control points, 243 quality control procedures and 47 procedure document reviews. Annual radiographic inspection films of the products exceed more than 400,000 copies and each product quality files keep for more than 20 years, so each weld quality can be tracked. HONGTU continues to carry out the LEAN Management, introduce the ONE module, passes the HSE system(quality, occupational health and safety, environment) certification and realizes the comprehensive management of information, quality and workers in the manufacturing site.06 Professional International Services and Marketing NetworkHONGTU has its own international business network and a sound international business organization structure, including 50 plus professionals engaged in technical service and overseas marketing, dedicated to providing overseas customers with technical consultation, business negotiation, product service, personnel training and a full range of integrated solutions services, and has built a three-level service assurance system comprised of salesperson, engineer and professional service personnel.